Why Diagnostics and Emission Maintenance Are Critical for Truck Fleets

Every truck fleet manager knows that the health and reliability of their vehicles go far beyond simple oil changes and routine tire rotations. Today’s commercial trucks, including industry workhorses like Hino Isuzu, and Mitsubishi Fuso, rely on a complex network of electronic control units, sensors, and advanced emission control systems to operate efficiently, meet regulatory standards, and deliver operational consistency. This is why diagnostics and emission maintenance have become cornerstones of modern fleet management, detailing not just the “what” but also the “why” behind systematic vehicle care.

Diagnostics in the context of auto and truck service is the comprehensive process technicians use to interpret and analyze the countless signals generated by a vehicle’s control systems. While every modern Hino truck comes equipped with an onboard diagnostics system, these built-in systems are just the tip of the iceberg, alerting drivers to immediate or obvious faults, usually through dashboard lights or error codes. However, professional diagnostic services at Tire Domain dig much deeper, utilizing manufacturer-grade tools and software. These advanced diagnostics can access proprietary modules, revealing intermittent faults, sensor wear, and early-stage failures long before they become a crisis. By relying on Hino truck emission diagnostics at Vaughan’s Tire Domain, fleet managers ensure that small issues are identified proactively, reducing the cost and impact of repairs while supporting regulatory compliance.

Proactive diagnostics, especially on vehicles like Hino trucks, play a pivotal role in minimizing downtime and enhancing reliability. Unchecked faults can escalate, causing breakdowns that leave trucks stranded and schedules in disarray. That’s why Tire Domain combines regular Hino truck emission diagnostics at our Vaughan repair centre with predictive maintenance planning to anticipate component wear and software issues before they disrupt operations. This translates directly into more consistent uptime, improved driver confidence, and a longer, more reliable service life for each vehicle.

Fuel efficiency and reduced emissions go hand in hand, and when regular diagnostics flag deteriorating injectors, aging sensors, or emissions system warnings, Tire Domain can address these concerns through targeted maintenance. By responding to diagnostic data quickly, operators see measurable gains in fuel economy and cleaner tailpipe emissions. The savings, both in fuel costs and potential non-compliance penalties, can be significant, especially across a large fleet of Hino vehicles.

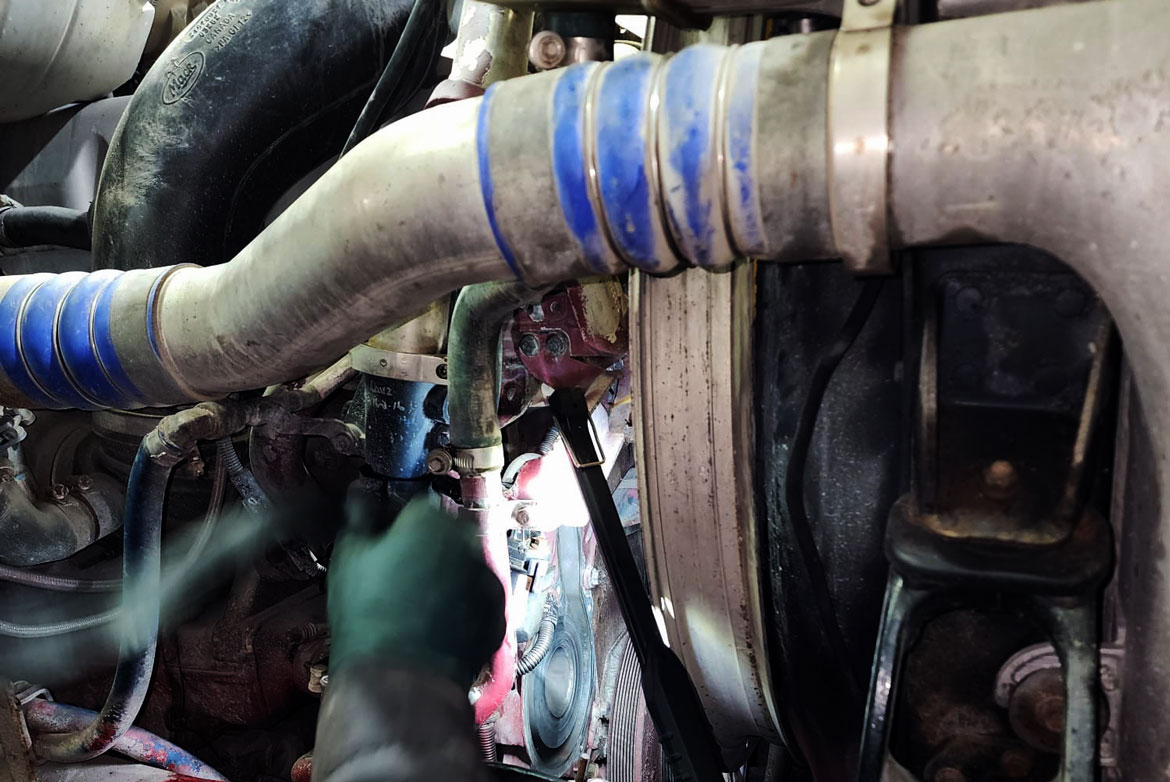

Central to this entire process is the diesel after-treatment system. This intricate suite of components— including the diesel particulate filter (DPF), selective catalytic reduction (SCR) system, and oxidizing catalysts— is what enables modern trucks to meet environmental regulations. Hino diesel after-treatment system maintenance at our Vaughan repair centre is crucial, because any neglect can result in not just performance losses but regulatory fines and downtime. Debris buildup in the DPF, for example, can cause exhaust restriction, engine warning lights, and even force the truck into a restricted operating mode known as regen limp.

Understanding regen limp is essential for every Hino operator. When the vehicle cannot safely or effectively burn off accumulated particulates in the DPF (a process called regeneration), it will limit power to prompt a service intervention. We provide Hino truck regen limp solutions at our Vaughan repair centre by identifying the root causes— whether that’s faulty sensors, poor fuel quality, or neglected filter maintenance. Failed or incomplete regenerations not only impact performance but also escalate to an engine derate, where the engine’s control module will further reduce available power to prevent catastrophic emissions system failure. Letting us find the right Hino truck regen limp solution at our Vaughan repair centre can mean the difference between a simple shop fix and a lengthy, costly recovery operation.

Similarly, engine derate is strongly connected to emissions system faults. A derate is essentially the truck’s way of self-preservation, but to fleet operators, it means decreased speed, reduced hauling capacity, and costly delays. To find the appropriate Hino truck engine derate solution at Vaughan’s Tire Domain, we use a comprehensive approach, diagnosing software, sensors, and hardware to restore power output and prevent recurrent issues. When drivers encounter a derate scenario, quick access to a reliable Hino truck engine derate solution, like those at Vaughan’s Tire Domain, not only restores operations faster but safeguards the engine and emissions system from long-term damage.

Ultimately, these interconnected systems require the skills of qualified diesel technicians. For your Hino diesel after-treatment system maintenance look to Vaughan’s Tire Domain to avoid fines, reduce downtime, and realize total cost-of-ownership savings. Tire Domain has set the standard in keeping fleets compliant, efficient, and on the road with proactive care and unrivaled technical expertise, demonstrating why diagnostics and emission maintenance are absolutely critical for every commercial truck fleet.